Task 1 – parametric 3D design

In this task we had to create a series of parametric 3D designs that can be fabricated using laser cutting. We made algorithms to to tune the parameters to create different variations.

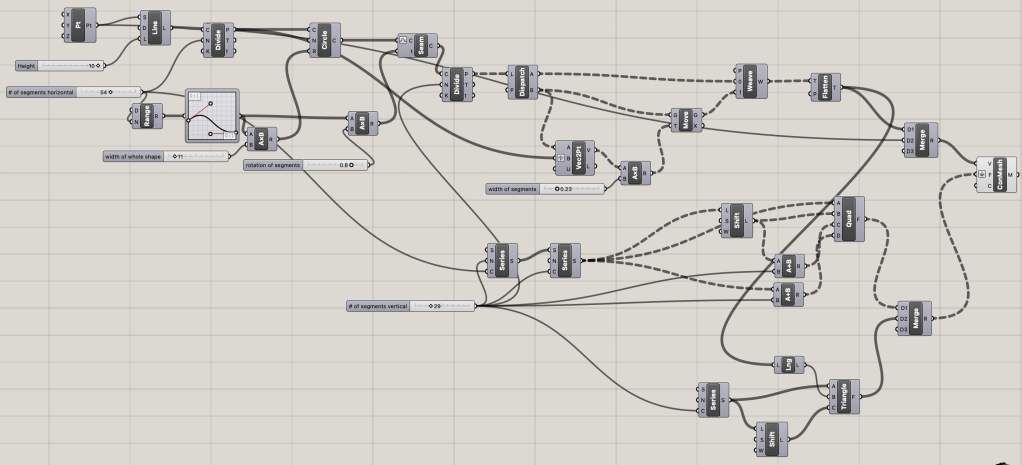

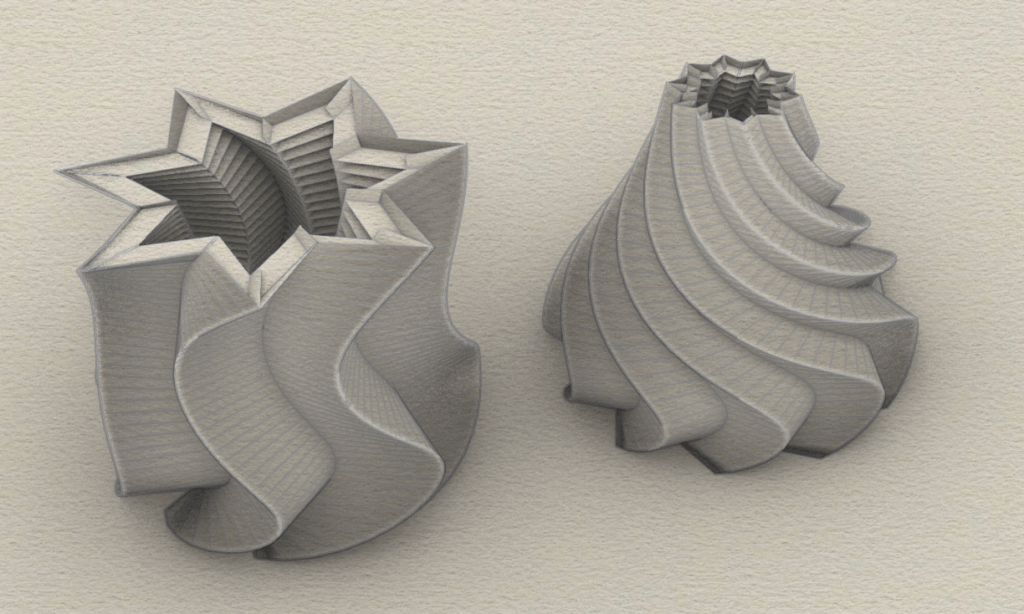

I followed the youtube tutorial to create basic parametric vases, and had 7 tunable parameters. Those were 1) the height of the vase, 2) the number of vertical segments, if you make this number higher it will look smoother because there will be more sides, 3) the number of horizontal segments, if you make this number higher it will also make it look smoother, 4) the width of the shape, 5) the width of the individual segments, will make the top of the vase opening smaller or larger, 6) the rotation of the segments, makes it more or less circular/star-like, 7) a graph that adjusted the vase shape, which includes the width of certain sections, the size of the opening and base, and where the biggest part of the vase was positioned.

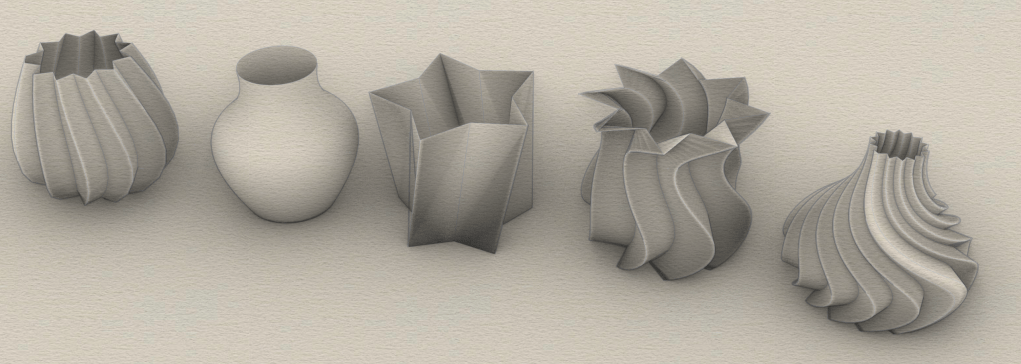

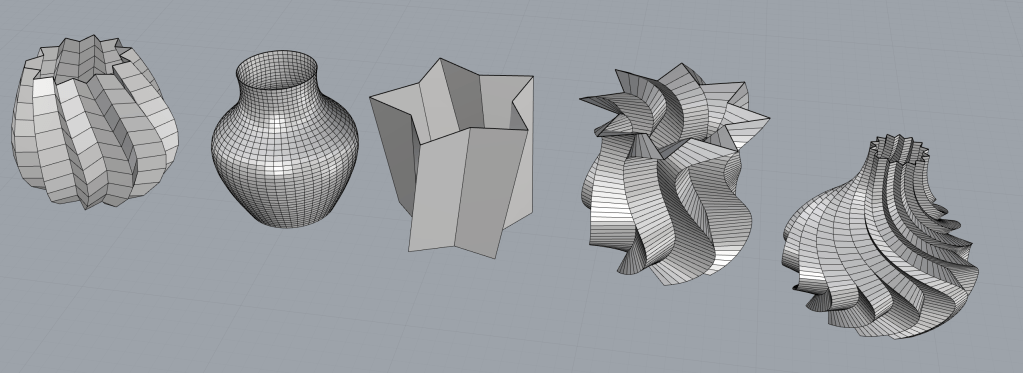

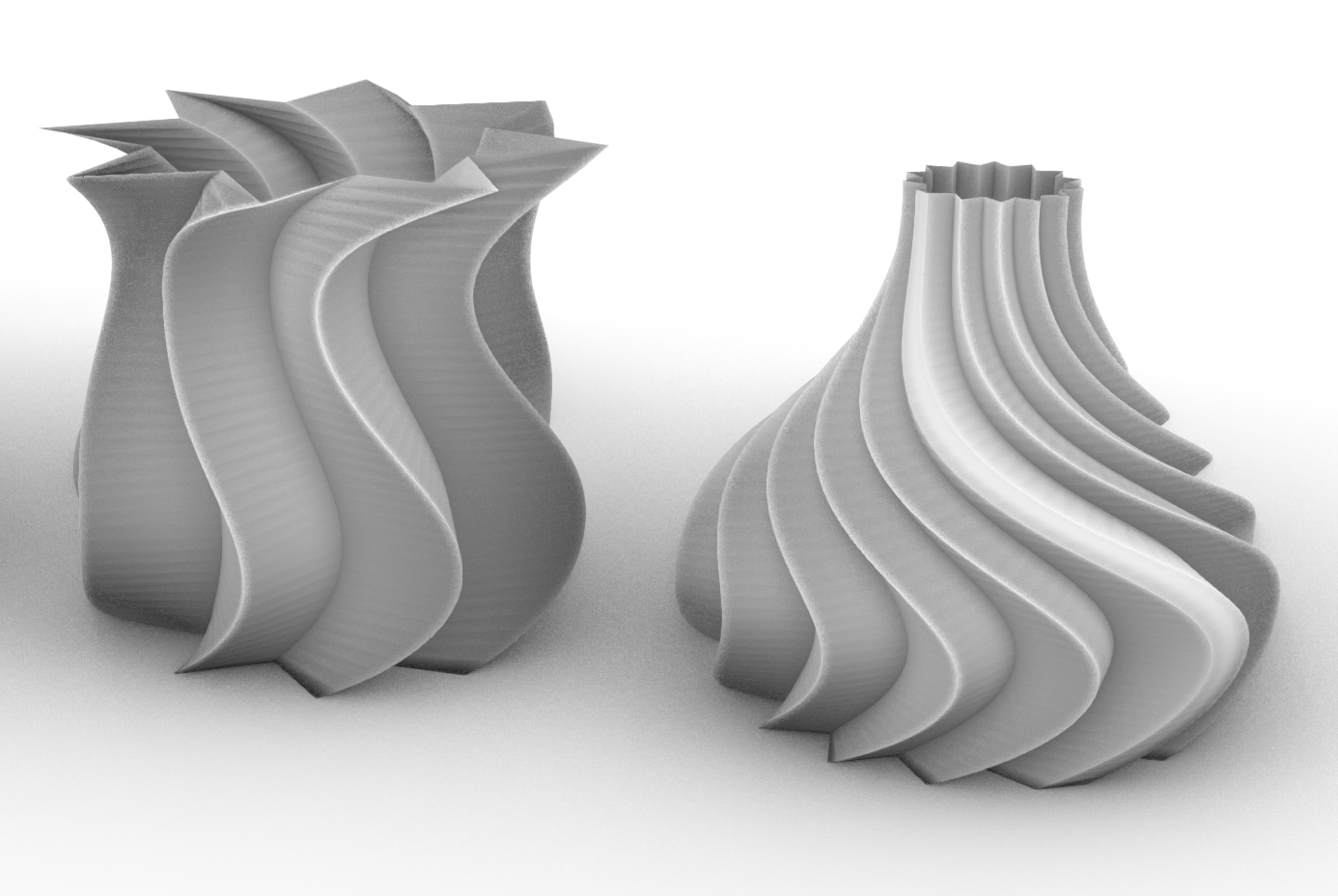

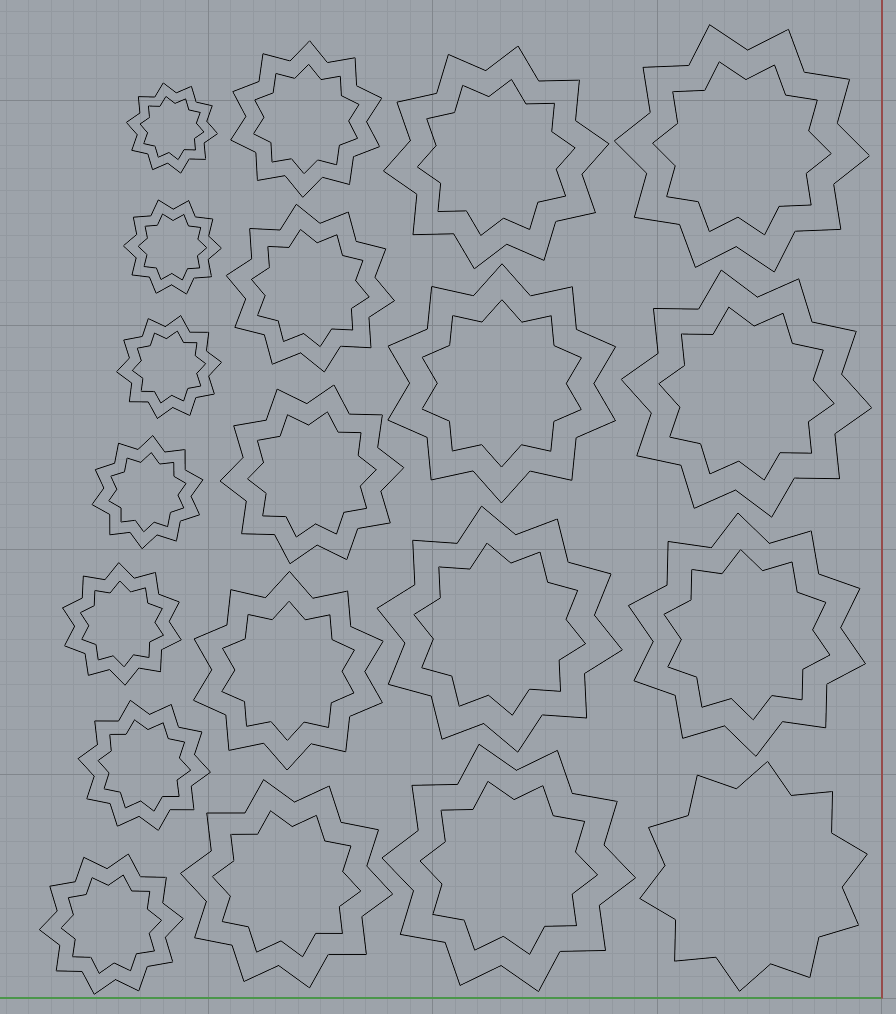

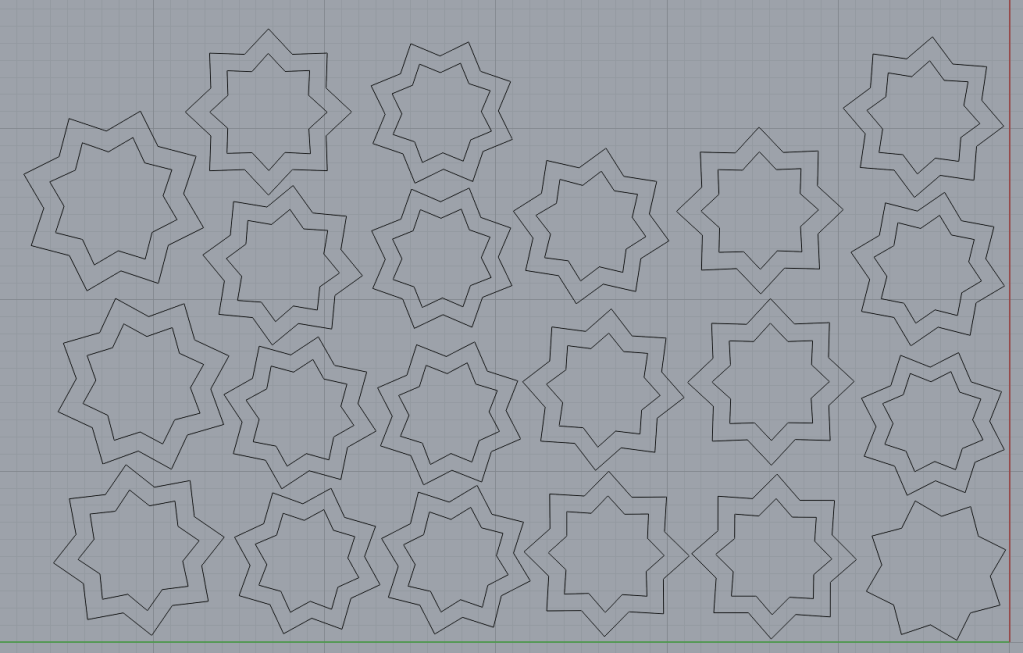

Here are some different outputs of the 5 vases I made. I decided to go with printing the 2 vases on the right.

part 2 – creating a 3D-2D slicer

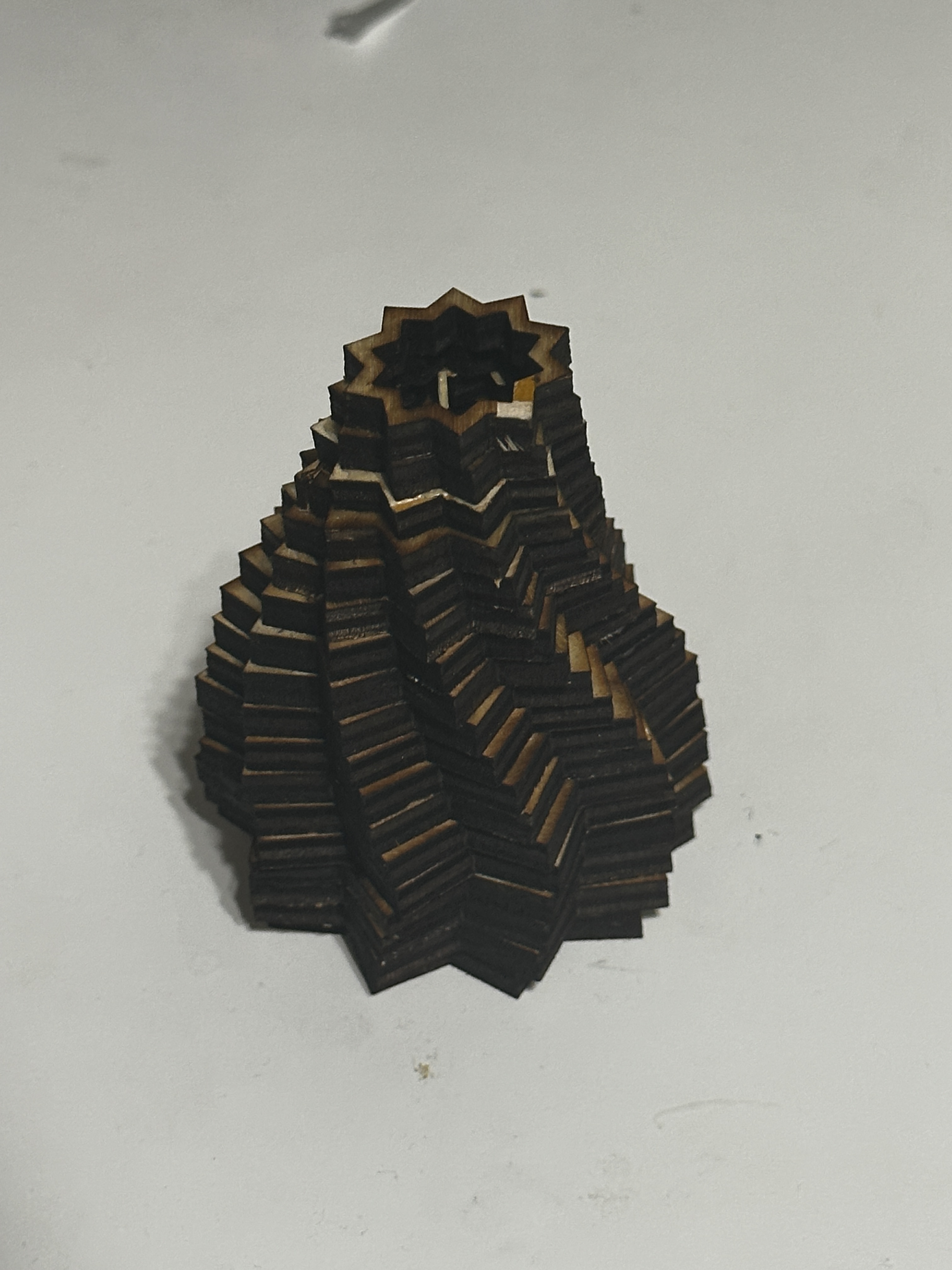

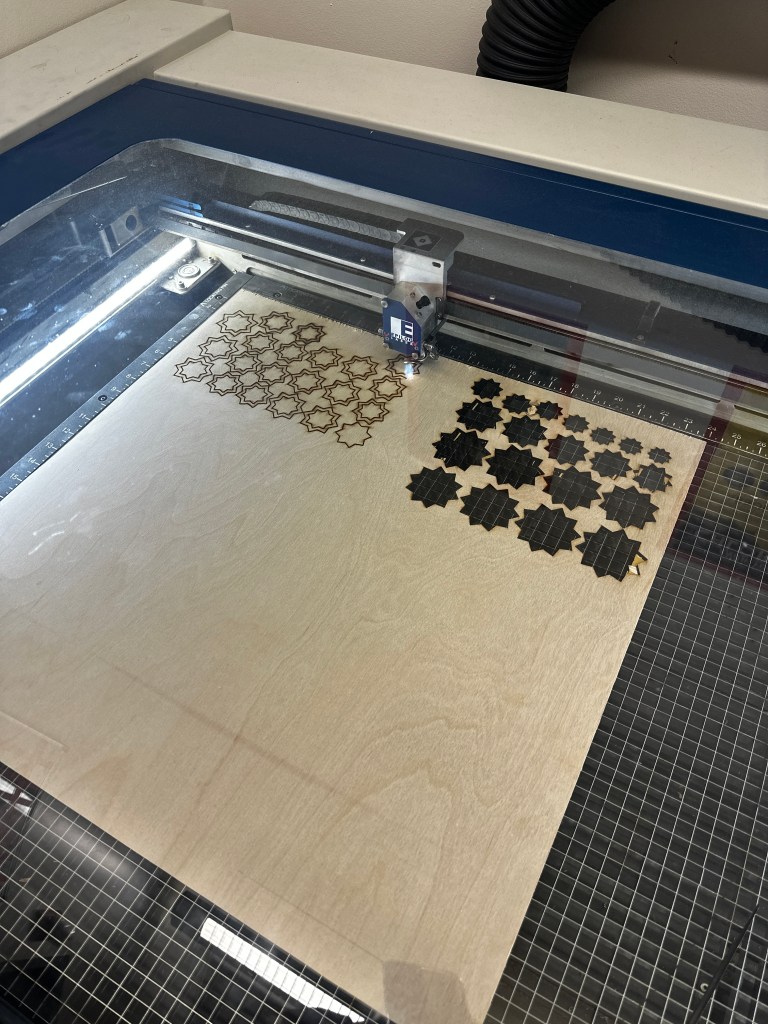

In this task we built a slicer that converts 3D geometry into a series of laser cuttable “2D” slices that can be stacked together to form the original shape, where the slicer will be parametrized based on material thickness.

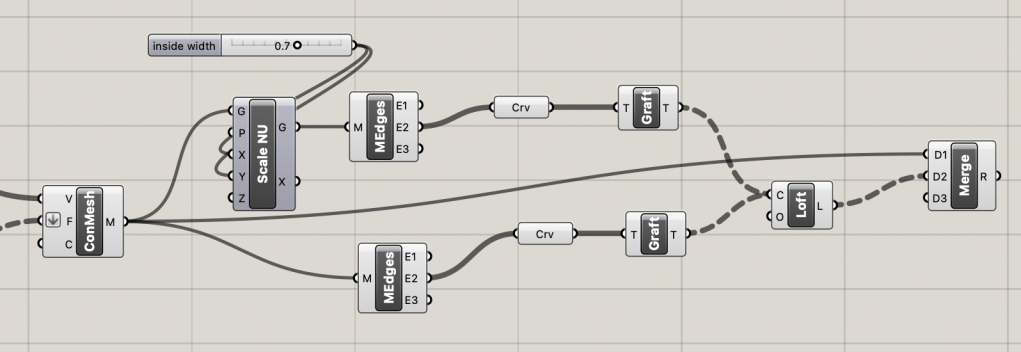

I originally had the vases with no internal thickness, but since I want to laser cut these vases I updated my grasshopper code to include a tunable parameter to make the hole of the vase bigger or smaller. I got the edge of the inside part of the vase and the edge of the outside of the vase and bridged them together, then exported that bridge and the original output together. Here is that grasshopper code

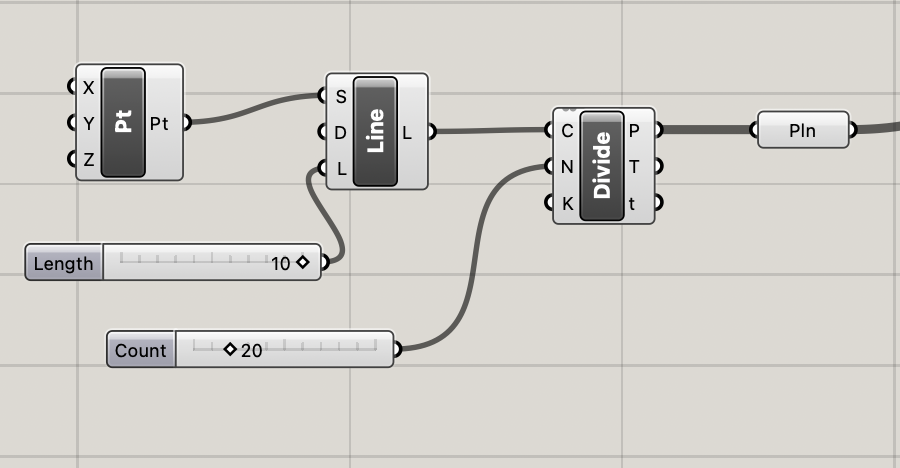

Next was creating the slicer. Since grasshopper is unit-less, I decided to make every 2 bars (in the sliders for hight and width) be equal to 1 inch so my total shape would be 5×4 inches (actually a bit larger because the base was expanded a bit. I made sure there would be 20 planes, because the total hight is 5 and divided by the thickness of the material, which would be an 1/4 of an inch. (4 cuts to get an inch, 5 inches, 4*5 = 20).

I had to eventually print with a material thicker than what I put through my algorithm, so the vases are a bit taller than the 3d models.

Leave a comment